SPECIFICATIONS

Standard Features | ||||||

| Patented Smart Balance System | ||||||

| 400 G spinning power | ||||||

99 independent programmable recipes (up to 100 programming steps each) |

||||||

| Spin Dye (JET Spraying) Process with variable dyeing speeds | ||||||

| Direct steam and Indirect steam heating system through external heat exchanger | ||||||

| Chemical/Dye Kitchen with progressive dosing | ||||||

| Ramp controlled heating and cooling (Cool Down) | ||||||

| Inverter controlled motor drive | PLC Controlled SWC 2000 Electronic Control System | |||||

| 99 independent programmable recipes (up to 100 programming steps each) | Forward tilting system for unloading (N/A for Miracle 60) | |||||

| Single motor drive with smaller power | Stainless steel front cover plate and 316 L quality stainless steel for parts coming into contact with chemicals | |||||

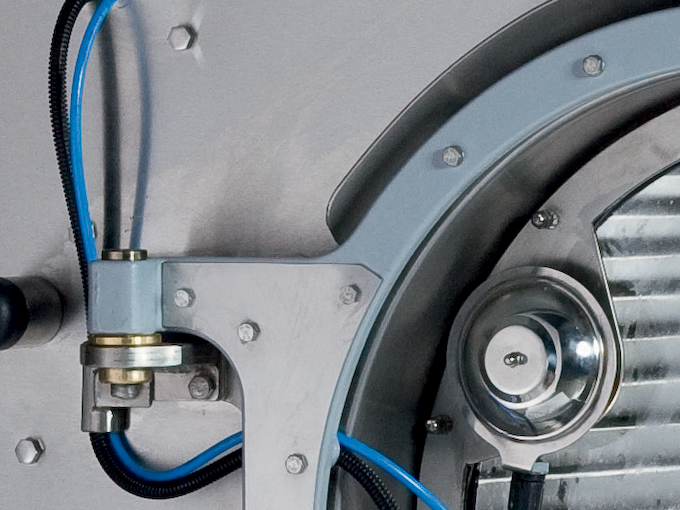

| Continuous water level measurement | No hydraulics, all pneumatic control system | |||||

| One main chemical compartment | 2 water inlet control (Hot, cold) | |||||

| Direct steam and Indirect steam heating system through external heat exchanger | ||||||

| Chemical/Dye Kitchen with progressive dosing | ||||||

| One large drain outlet with air operated water release valve | Special separated leak proof bearing system | |||||

| Viton seals around shaft with spares | Automatically locked front loading door with safety lock | |||||

| Water sampling valve | Front panel bumper rail | |||||

Optional Features | ||||||

| PolyRib ECO Drum (Patent Pending) | ||||||

| Cleanseal sealing dust removal system | 2nd drain and 3rd water inlet control | |||||

| Automatic door | PH Control System | |||||

| 8 or 16 external, electrically controlled chemical inlet outputs | SCADA (System Controls and Data Acquisition) and Network applications | |||||

|

The GD-SM series Sample Dyeing Machines are designed to perform for checking the correctness and accuracy of the processes before starting the bulk production. Even same features of Smartex Miracle bulk production. Even same features of Smartex Miracle bulk production machines such as PolyRib ECO Drum, Spin Dye Jet Spraying System, and Smart Balancing System come along with the machine as standard. These supreme features provide you a perfect matching of samples and prevent loosing of time and huge losses in terms of pieces. Again with the help of Spin Dye and PolyRib ECO Drum, all undesired crises and abrasions are eliminated even though with lowest liquor ratios of 1:2 or 1:3 in dyeing. Comparing to conventional sample dyeing machines, 50% saving from water, chemicals, heating energy and waste water is possible. PLC controlled SC 400 control system is working compatible with auto dosing, chemical kitchen for progressive dosing, indirect heating, powder dissolving, continuous level measurement, tank cleaning, bath recirculation etc and external heat exchanger for accurate ramp controlled heating and cooling. |

||||||

| All capacities are capable of exerting 400 G force without any vibration with the help of Smart Balancing System (patented). Extraction at 400 G saves about 20% in energy spent on. Again independent of the load distribution within the drum, stable balancing is achieved by Smart Balancing System, thereby almost eliminating the need for restarts. All mechanical parts of the machine are not subject to fatigue caused by vibration. | ||||||

| Comparing with the conventional dyeing machines, SMARTEX Miracle pays back its investment within 6 to 10 months according to installed region conditions. Meet with 21st century’s technologies. A cigarette can stand vertically while spinning at max speeds. |

||||||

|

The HWE-SEM series Sample Washing Machines are designed to perform for checking the correctness and accuracy of the processes before starting the bulk production. Even same features of Smartex Miracle bulk production. Even same features of Smartex Miracle bulk production machines such as PolyRib ECO Drum, Spin Dye Jet Spraying System, and Smart Balancing System come along with the machine as standard. These supreme features provide you a perfect matching of samples and prevent loosing of time and huge losses in terms of pieces. Again with the help of Spin Dye and PolyRib ECO Drum, all undesired crises and abrasions are eliminated even though with lowest liquor ratios of 1:2 or 1:3 in dyeing. Comparing to conventional sample dyeing machines, 50% saving from water, chemicals, heating energy and waste water is possible. Smartex HWE-SM series are capable of exerting 400 G force during extraction which saves 20% from drying time and drying energy. |

IMAGES