SPECIFICATIONS

| 10 | 12 | 20 | 30 | 40 | ||||||||

| 610 mm | 762 mm | 915 mm | 915 mm | 915 mm | ||||||||

| 345 mm | 410 mm | 460 mm | 460 mm | 610 mm | ||||||||

| 100lt | 120lt | 208lt | 300lt | 400lt | ||||||||

| 360 mm | 360 mm | 475 mm | 475 mm | 475 mm | ||||||||

| 47 rpm | 47 rpm | 45 rpm | 40 rpm | 40 rpm | ||||||||

| 76 rpm | 76 rpm | 65 rpm | 63 rpm | 63 rpm | ||||||||

| 300 G | 300 G | 300 G | 300 G | 300 G | ||||||||

| 450 rpm | 450 rpm | 400 rpm | 360 rpm | 360 rpm | ||||||||

| 700 rpm | 700 rpm | 650 rpm | 650 rpm | 600 rpm | ||||||||

| 950 rpm | 950 rpm | 840 rpm | 770 rpm | 770 rpm | ||||||||

| 1 1/2" | 1 1/2" | 1 1/2" | 2 1/2" | 2 1/2" | ||||||||

| 3/4 " | 3/4 " | 3/4 " | 3/4 " | 3/4 " | ||||||||

| 1/2" | 1/2" | 1/2" | 1/2" | 1" | ||||||||

| 1.5 KW | 2.2 KW | 3 KW | 4 KW | 5.5 KW | ||||||||

| 6 KW | 9 KW | 9 KW | 15 KW | 18 KW | ||||||||

| 825 mm | 825 mm | 990 mm | 1180 mm | 1180 mm | ||||||||

| 1170 mm | 1350 mm | 1515 mm | 1780 mm | 1780 mm | ||||||||

| 865 mm | 915 mm | 1120 mm | 1245 mm | 1495 mm | ||||||||

| 370 kg | 495 kg | 595 kg | 1020 kg | 1300 kg | ||||||||

| 50 | 60 | 80 | 100 | |||||||||

| 915 mm | 1092 mm | 1320 mm | 1320 mm | |||||||||

| 760 mm | 642 mm | 590 mm | 735 mm | |||||||||

| 500 lt | 600 lt | 800 lt | 1000 lt | |||||||||

| 475 mm | 700 mm | 700 mm | 700 mm | |||||||||

| 40 rpm | 34 rpm | 38 rpm | 38 rpm | |||||||||

| 63 rpm | 62 rpm | 49 rpm | 49 rpm | |||||||||

| 300 G | 300 G | 300 G | 300 G | |||||||||

| 360 rpm | 340 rpm | 320 rpm | 320 rpm | |||||||||

| 600 rpm | 580 rpm | 500 rpm | 500 rpm | |||||||||

| 770 rpm | 700 rpm | 640 rpm | 640 rpm | |||||||||

| 2 1/2" | 2 1/2" | 2 1/2" | 2 1/2" | |||||||||

| 1" | 1" | 1 1/4" | 1 1/4" | |||||||||

| 1" | 1" | 1" | 1" | |||||||||

| 7.5 KW | 11 KW | 15 KW | 18.5 KW | |||||||||

| 24 KW | 36 KW | -- | -- | |||||||||

| 1180 mm | 1690 mm | 1710 mm | 1710 mm | |||||||||

| 1780 mm | 2060 mm | 2060 mm | 2060 mm | |||||||||

| 1565 mm | 1770 mm | 1730 mm | 1820 mm | |||||||||

| 1450 kg | 2050 kg | 2990 kg | 3220 kg | |||||||||

Standard Features | ||||||||||||

| Fully Satinless Steel Outer Structure | ||||||||||||

| Stainless Steel Inner and Outer Drum | ||||||||||||

| 300 G Extraction Force | ||||||||||||

| Single Motor Drive with Inverter Frequency Control | ||||||||||||

| Free Standing. No Fixing on the ground with Developed Springs and Shock Absorbers | ||||||||||||

| ST-37 Steel Balance Weight System | ||||||||||||

| Maximum Control Panel | ||||||||||||

| Cool down | ||||||||||||

| Aluminum Main Rim System | ||||||||||||

| CE, TSE and ISO 9001-2000 | ||||||||||||

| 50 Programmable Recipes (13 Stable and Reprogrammble, 99 Steps each) | ||||||||||||

| CE, TSE and ISO 9001-2000 | ||||||||||||

| Adjustable Extraction Speed | ||||||||||||

| Adjustable Water Temperature | ||||||||||||

| Adjustable Water Level | ||||||||||||

| Adjustable Washing Time | ||||||||||||

| Manual Interference during the process | ||||||||||||

| Manual Operating of each step | ||||||||||||

| Logging if last 30 Errors | ||||||||||||

| Tracing of each washing step by LEDs | ||||||||||||

Optional Features | ||||||||||||

| 35 % saving from Water, 15 Tons per year saving from water for 1 KG Dry Laundry, 25 % Saving from rinsing time, 48 Days per year Labor Saving for each machine | ||||||||||||

| 2nd Drain | ||||||||||||

| 3rd water Inlet | ||||||||||||

| External chemical inlet signals | ||||||||||||

General Information | ||||||||||||

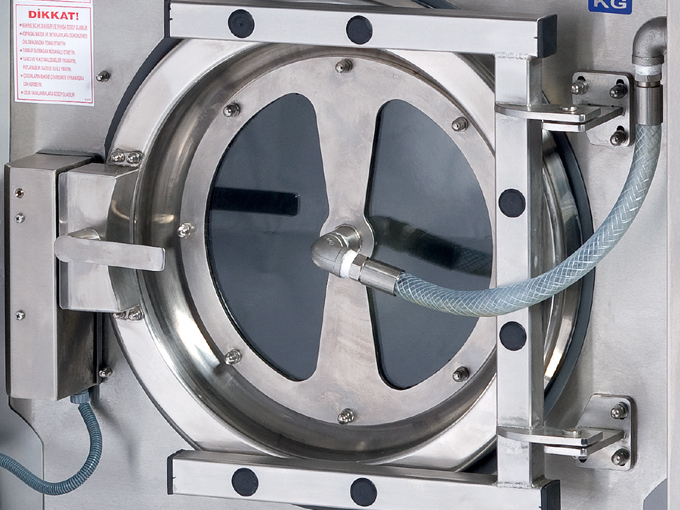

| Tolkar extra washer extractors are mainly designed to perform the most demanding washing tasks of laundries. Full main as sides, top, front plate, inner/outer drum and parts coming into contact with chemicals are constituted form 304 I quality stainless steel. 5 electrically controlled chemical intake compartments allowing powder or liquid chemicals are provided standard. High speed extraction force of 300 G ensures the savings from drying or ironing time and energy. Aluminum alloyed main pulley helps the drive system by reducing the loads come onto the motor. Newly introduced Tolkar control system includes 37 reprogrammable cycles where 13 of them are already programmed. All automatic steps can be interrupted and controlled manually. Main problem with the washer extractors’ is homogenous wetting of laundry and chemical distribution during water intake. As most of the machines’ drums are stopped during this process, drums of Tolkar machines start rotating in the same time with water intake process. This ensures homogenous distribution of water and chemical which provides best washing results. New balance weight system comprised from st 37 steel, serves for a long time as it does not crack or break like concrete balance weight systems. Heavy duty springs and shock absorbers eliminate the needs for floor installation as even during high spinning speeds, machine is free standing. Electro polished and engineered drum design with its perforation is suitable for delicates. Viton seals around the shaft protect the bedding and bearing mechanisms where mentioned seals resist the high spinning speeds, high temperatures and chemicals. Anti balance switches cut off the mains in case of any imbalance or errors in order to prevent fatal damages. | ||||||||||||

IMAGES