SPECIFICATIONS

Standard Features | ||||||

| Belt – Pulley Drive System |

||||||

| Pre Extraction in built | ||||||

| Direct steam heating | ||||||

| Stainless steel front cover plate and 316 L quality stainless steel for parts coming into contact with chemicals | ||||||

| 3+3 mm stainless steel inner drum | ||||||

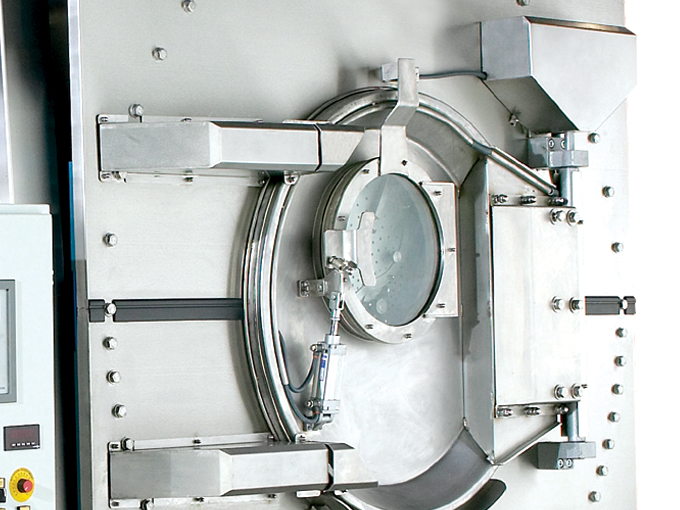

| Sample Door with security glass | ||||||

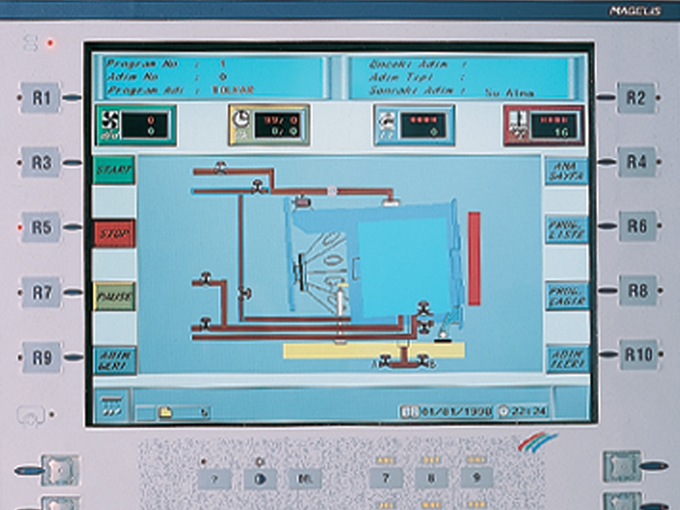

| Microprocessor Controlled 99 independent programmable recipes (up to 100 programming steps each) | ||||||

| Forward tilting system for unloading | ||||||

| TOM system (Data transferring from m/c to m/c) | ||||||

| Manual Control Panel | ||||||

| Double direction working capability | ||||||

| Adjustable water intake level in liters | ||||||

| Epoxy based paint on main body (Chemical and water resistant) | ||||||

| Automatic front door | ||||||

| Automatic shutter system for safety | ||||||

| Pneumatic locking system for loading and sample doors provided with pistons | ||||||

| C4140 quality steel main shaft | ||||||

| 5 years guarantee for against leakage around main shaft | ||||||

| Sample water tap | ||||||

| Sample step | ||||||

Optional Features | ||||||

| Direct Drive System (No belt-pulleys) | ||||||

| External Chemical/Dye Dispensing Unit, 3 tanks main with stirrer | ||||||

| SCADA (System Controls and Data Acquisition) and Network Applications | ||||||

| 2nd drain and 3rd water inlet control | ||||||

| Main shaft hardening process with 10 years of guarantee | ||||||

| Program transferring from PC to machines with TOM System | ||||||

| Stainless steel covering for all columns and front face | ||||||

| Detachable Y Drum with revolving door, sampling door synchronized with revolving door | ||||||

| Tolkar textile washing machines offer you unlimited alternatives of washing effects with most economic investments. Especially for stone washing applications, Tolkar machines serve you for long years with its robust design and stable construction. Microprocessor controlled maestro tower is allowing you to control the machine both automatically and manually. Standard forward and backwards tilting helps you during loading, unloading and processing without damaging the garments where this is suitable for delicates as well. |

||||||

| Direct drive system eliminates the needs of belt pulleys from the system wherein drive system failure risks are minimized due to tension losses of V-belts. Front cover plate, parts coming into contact with chemicals are made by 316 L stainless steel along with main chemical tank. Sample step operated consistently with sample door, helps to reach the samples quickly. With TOM Systems, recipes can be transferred from machine to machine or PC to machine/machine to PC easily. Optionally offered TOLKAR Cat Eye Scada System generates the control whole processes professionally in details by collecting the reports along with required data. |

IMAGES