SPECIFICATIONS

Standard Features | ||||||

150 |

225 |

340 |

500 |

|||

| Capacity (kg) | 150 | 225 | 340 | 500 | ||

| Drum Volume (lt) | 1480 | 2280 | 3398 | 4800 | ||

| Drum Diameter (mm) | 1240 | 1480 | 1720 | 1720 | ||

| Drum Depth (mm) | 1220 | 1330 | 1465 | 2070 | ||

| Washing Speed | Adjustable-Variable |

|||||

| Max Extraction (rpm) | 760 | 700 | 645 | 645 | ||

| Max G Force (G) | 400 | 400 | 400 | 400 | ||

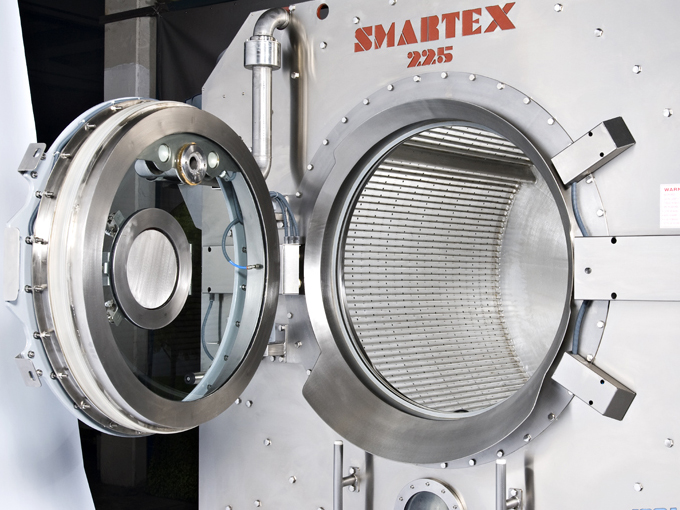

| Door Diameter (mm) | 710 | 850 | 1000 | 1000 | ||

| Drain Valve Dia. (inch) | 5 | 6 | 8 | 8 | ||

| Chemical Inlet | 1 MAIN CHEMICAL INLET |

|||||

| Motor Speed Control | Standard |

|||||

| Washing & Spinning (kw) | 5.5 | 7.5 | 11 | 18.5 | ||

| Total Electric Power (kw) | 6.5 | 8.5 | 12 | 19.5 | ||

| Water Intake (inch) | 1 1/2 | 1 1/2 | 2 | 2 | ||

| Steam Intake (inch) | 3/4 | 1 1/4 | 1 1/2 | 1 1/2 | ||

Dimensions |

||||||

| Width (mm) | 1610 | 1915 | 2175 | 2200 | ||

| Height (mm) | 1950 | 2275 | 2550 | 2550 | ||

| Depth (mm) | 2350 | 2590 | 3045 | 3650 | ||

| Weight (kg) | 3250 | 5200 | 6600 | 9000 | ||

| Patented Smart Balance System | ||||||

| 400 G spinning power | ||||||

| Spin Dye (JET Spraying) Process with variable dyeing speeds | ||||||

| Direct steam and Indirect steam heating system through external heat exchanger | ||||||

| External Chemical/Dye Kitchen with progressive dosing (3 tanks or more, main with stirrer. Main tank with bath liquor dissolving, continuous level measurements, indirect steam heating, powder/salt dissolving, hot water intake capabilities | ||||||

| Ramp controlled heating and cooling (Cool Down) | ||||||

| Inverter controlled motor drive | ||||||

| PLC Controlled SWC 2000 Electronic Control System(Cool Down) | ||||||

| 99 independent programmable recipes (up to 100 programming steps each) | ||||||

| Forward tilting system for unloading (N/A for Miracle 60) | ||||||

| Single motor drive with smaller power | ||||||

| Stainless steel front cover plate and 316 L quality stainless steel for parts coming into contact with chemicals | ||||||

| Continuous water level measurement with industrial water counter | ||||||

| Operating temperature up to 99 C | ||||||

| Variable and adjustable dyeing, washing, and spinning speeds | ||||||

| Heat insulated outer drum | ||||||

| No hydraulics, all pneumatic control system | ||||||

| One main chemical compartment | ||||||

| 2 water inlet control (Hot, cold) | ||||||

| One large drain outlet with air operated water release valve | ||||||

| Special separated leak proof bearing system | ||||||

| Revolution counter | ||||||

| Viton seals around shaft with spares | ||||||

| Automatically locked front loading door with safety lock | ||||||

| Water sampling valve | ||||||

| Front panel bumper rail | ||||||

| 2 water, 1 steam valve and connection hoses | ||||||

| Carrier wheels for easy installation and maintenance | ||||||

Optional Features | ||||||

| PolyRib ECO Drum (Patent Pending) | ||||||

| PH Control System | ||||||

| Cleanseal sealing dust removal system | ||||||

| 8 or 6 external chemical intake control | ||||||

| Industrial type Water liter counter | ||||||

| Backward tilting 2nd drain and 3rd water inlet control | ||||||

| Automatic door Water sampling valve | ||||||

| SCADA (System Controls and Data Acquisition) and Network applications | ||||||

| Automatically controlled grease lubricator for bearings | ||||||

| Y Drum with revolving door, sampling door synchronized with revolving door | ||||||

| TOLKAR/SMARTEX Professional chemical/dye kitchens are designed to perform the most demanding garment dyeing tasks with its supreme features. 3 large tanks, main with stirrer and bath liquor dissolving, continuous level measurements, indirect steam heating, powder/salt dissolving, hot water intake and transfer to auxiliary tanks allow achieving absolute dyeing results during long processes. External heat exchanger supported system provides homogenous and precision ramp controlled heating and cooling in order to obtain a perfect penetration on fabrics. | ||||||

|

| ||||||

| TOLKAR/SMARTEX CAT EYE SCADA (System Control and Data Acquisition) software package is developed specially for TOLKAR & SMARTEX Garment Dyeing and Textile Washing machines for the professional user. The system concept allows the user to handle dye and wash recipes on the machine. | ||||||

|

| ||||||

| The GD series are designed to perform the most demanding garment dyeing tasks. Most of the equipment required for dyeing come along as standard features in this series: SPIN DYE dyeing method that reduces the liquor ratio to 1:5 at the reactive and direct dyeing, 1:6/1:7 at pigment dyeing, indirect steam heating, chemical/dye kitchen unit, cool down etc… | ||||||

| By using the newest technology for the garment dyeing process, called SPIN DYE SYSTEM, SMARTEX has made obsolete the Y drum partitioning of the drum. The result is higher quality, easier, more economic and competitive dyeing. As the garments do not fall, there is almost no mechanical abrasion effect on garments during the long process times. Thanks to its technology, unlike other producers, SMARTEX can produce the drums with low diameters. | ||||||

| Besides, Tolkar is proud to introduce Ultimate Dyeing Machine called MIRACLE Series with its new invention “PolyRib ECO Drum†(patent pending). The Poly-Rib™ drum, as we named it, is a revolutionary drum structure with multiple small ribs (wings) along with 3 smaller beaters. This drum structure provides homogenous penetration of dyes onto the fabrics, therefore increasing the effectiveness of dyeing quality. Hence it is suitable for delicates by means of less mechanical action of multiple ribs. | ||||||

| The ECOâ„¢ Drum is also our other revolution in dyeing/washing technologies as TOLKAR id proud to introduce the ECOâ„¢ Drum. During dyeing/washing, wherein the passage of water is restricted with the help of PolyRib drum structure; passed water from the drum through lessened perforations to the tub is pumped back into the drum with a circulation pump through Spin Dye injector which is placed under the drum. Comprised invention called ECOâ„¢ Drumthat is used along with POlyRib. With said metod the gap area between inner drum and tub is completely depleted and no water kept in this area equals to 40-50 % of total required water volume of conventional machines and provides 40-50% savings from required water. By eliminating the unessential water which normally has to be kept in the gap area, water consumption reduces dramatically and depending on saved water, all chemicals, heating energy and waste water consumptions are reduced as same. | ||||||

| Reducing the water filled into drum is causing to use smaller motors where friction forces between drum and water are eliminated by keeping the gap area empty. This further allows to load the machines more than usual where economizes on electricity consumption. | ||||||

| All capacities are capable of exerting 400 G force without any vibration with the help of Smart Balancing System (Patented). Extraction at 400 G saves about 20% in energy spent on. Again independent of the load distribution within the drum, stable balancing is achieved by Smart Balancing System, thereby almost eliminating the need for restarts. All mechanical parts of the machine are not subject to the fatigue caused by vibration. Comparing with the conventional dyeing machines, SMARTEX Miracle pays back its investment within 6 to 10 months according to installed region conditions. Meet with 21st century’s technologies. A cigarette can stand vertically while spinning at max speeds. | ||||||